Neurosonology and Cerebral Hemodynamics 13, 2017:35–41

Ts. Koleva 1, E. Titianova 1,2

1 Clinic of Functional Diagnostics of Nervous System, Military Medical Academy – Sofia

2 Faculty of Medicine, Sofia University “St. Kliment Ohridski” – Sofia, Bulgaria

Abstract

Three-dimensional bioprinting is a new method for identical reproduction of biological tissues and organs by layering living cells. The technological process consists of three stages: (1) pre-bioprinting includes biopsy of the desired organ or tissue, depiction by computer (CT) or magnetic resonance imaging (MRI), creation of a virtual model, selection of cell culture, broths and technology; (2) bioprinting – setting a mixture of selected cells, broths and bioink in a special printer (Inkjet, Microextrusion or Laser-assisted), incubation and conversion of the mixture into a tissue with a subsequent nano-dimensional multi-layer printing of the target CT/MRI image; (3) post-bioprinting – a process of a biological stabilization of the resulting organ or tissue. The creation of biomaterials is achieved through different approaches: biomimicry (cultivation of identical microcellular and extracellular structures), autonomous self-assembly (through embryonic embedded replication of the corresponding cells, tissues and organs) and building “mini tissues” by integrating miniature structural and functional components. Nowadays, the application of the method is mostly experimental (for testing drugs, analyzing chemical, biological and toxic agents) and clinically limited in transplantology. It has been shown that a skin, bone, cartilage, and other tissues and some organs (ear, trachea, heart valves, blood vessels, etc.) can be successfully bioprinted. Recently the first human embryonic neural stem cells, GABAergic neurons and spontaneously active neural networks have been also reproduced. However the full bioprinting of liver and kidney is still incomplete.

Regardless the advantages of 3D-bioprinting (greater resistance of the organ, no risk of rejection and no need for immunosuppressive therapy), the method is still not routinely used mainly because of its very high price and the need for highly qualified multidisciplinary team. In the future, it is expected 3D-bioprintig to be combined with mini-invasive personalized robotic systems.

Brief historical data: The classic definition of “printing” is a process of repeated reproduction of identical text or other images using a printing press or peripheral device (printer) connected to a computer. Its foundations were laid in 1439 when the German goldsmith and pianist Johannes Gutenberg constructed the first mechanical printing press; by applying pressure to an inked surface he printed a pattern on a woodblock. This revolutionary discovery had a significant impact on the development of book printing, education, politics, religion and society. The world's first mechanical system was invented by the British mathematician Charles Babbage in the 19th century. By the end of the 20th century, 2D-printing dominated. It is only in the last 20 years that 3D-printing of mostly inorganic materials and objects is applied [32].

Historically, the principle of bioprinting has been known since 1986 when Chuck Hull patented a new method (U.S. Patent 4,575,330) called “stereolithography” [18]. It is based on printing thin layers of a given material under the influence of ultraviolet light, forming a solid three-dimensional structure. Three years later, the construction of different 3D-printers began. In the 1990s new materials were introduced: nanoparticles, polymer blend and powdered metals. In 1999 scientists from the Wake Forest Institute for Regenerative Medicine used a 3D printer to build a synthetic skeleton of human bladder [2] and in 2010, Organovo (San Diego, California), began manufacturing the first bioprinted blood vessels. For a short time, different tissues and organs were bioprinted, and in 2015 the first human embryonic stem cell [11].

A variation of the traditional bioprinting is the magnetic 3D-bioprinting. It uses biocompatible magnetic nanoparticles to print cells into 3D structures or cell cultures. Cells are tagged with magnetic nanoparticles (nanoshuttle) that magnetize them. Using external magnetic forces that mimic tissue structure and function, they can be quickly printed in specific 3D models [35].

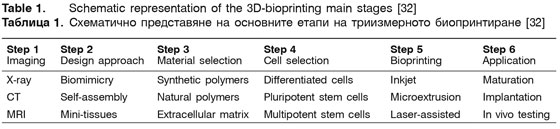

Bioprinting technology. Bioprinting is a complex process involving three main stages: (1) pre-bioprinting, (2) bioprinting and (3) post-bioprinting (Table 1).

Three approaches are used:

• Biomimicry – cultivation of identical microcellular and extracellular structures [18, 20, 34].

• Autonomous self-assembly – it is performed by embryonic embedded replication of the corresponding cells, tissues and organs [32]. Depending on their type, the cells create their own extracellular matrices. By cell signaling, sorting and modeling, they reproduce the tissue structure and function of the organ of origin (the so-called “scaffold-free” model) using their own cellular “spheroids” [30].

• Building “mini-tissues” – by integrating miniature structural and functional components [32].

Pre-bioprinting includes a biopsy of the desired organ or tissue. It starts with imaging the target structure by computer (CT) or magnetic resonance imaging (MRI), creation of a virtual model, selection of the cell culture, broths and technology. At this stage, the main used approach is biomimicry for cultivation of identical microcellular and extracellular structures [15, 19, 22, 32].

The second stage is the actual bioprinting. In a speciаl bioprinter (Inkjet, Microextruction or Laser-assisted), a suitable broth, mixture of selected cells and bioink are placed. Incubation and conversion of the mixture into a tissue with a subsequent nano-dimensional multi-layer printing of the target CT/MRI image are performed [4, 8, 32].

The process finishes with post-bioprinting and biological stabilization of the organ or tissue. The end product is an identical copy of the required model, possessing to a great extent (except for kidney and liver) the anatomical and functional characteristics of the original organs and tissues [7, 32].

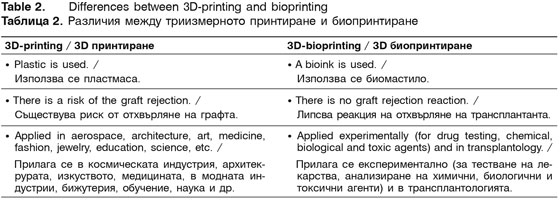

There are several principal differences between 3D-printing and bioprinting, which are shown in Table 2.

Regardless of the technological improvement of the bioprinting process observed in recent years, there are still a number of technological barriers related to creating a stable bioink, a suitable bio-environment for reproducing functional tissues and organs, minimisation and personalisation of printers, etc. [24].